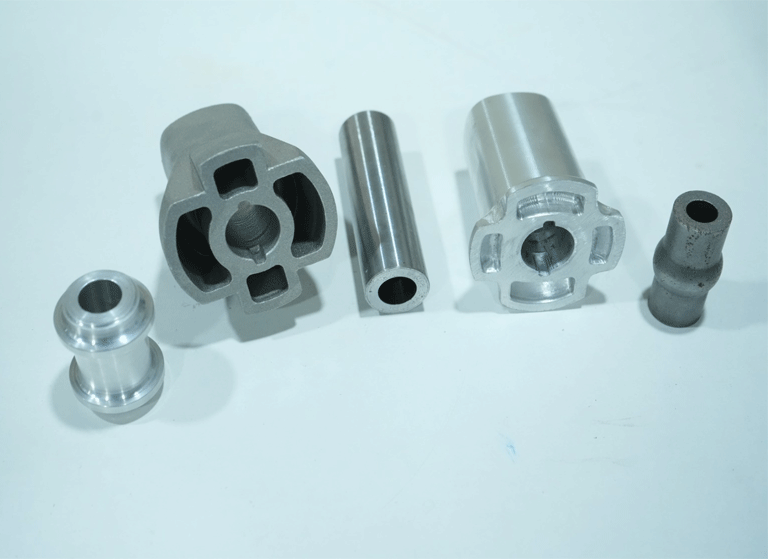

Aluminum and Steel Inner for Suspension Assly In 3D

- Home

- Aluminum and Steel Inner for Suspension Assly In 3D

Aluminum and Steel Inner for Suspension Assly In 3D

Aluminum and steel inner components for suspension assemblies are precisely engineered parts designed using advanced 3D modeling and CAD techniques to ensure perfect fit, strength, and performance. Aluminum inners provide lightweight characteristics, corrosion resistance, and improved ride efficiency, while steel inners offer high tensile strength, durability, and load-bearing capability. These components are commonly used in automotive and off-highway suspension systems where accuracy and reliability are critical. 3D design and simulation enable optimized geometry, tight tolerances, and seamless integration within the suspension assembly, resulting in enhanced stability, reduced wear, and long service life under demanding operating conditions.

About Us

Chakrapani Engineers is a Engineering Startup firm Established on 1st April 2025 By Founder and Proprietor - Mrs Shital D Pawar , Company Managing Director – Mr. Dnyaneshwar Y Pawar , Company MD is Having 25 Years of Rich Experience in Manufacturing and Processing

Useful Links

Our Products

Our Location

- Gat no 55 , Shiv Sai Chowk , Yelwadi Bypass Road , Yelwadi , Khed , Pune , Maharashtra , India Pin Code – 412109

- +91 8007629830

- sales@chakrapanigineers.com

© 2025 Copyright CHAKRAPANI ENGINEERS PVT. LTD. | All Rights Reserved | Design & Develope By Olatech Solutions

Total views : 796

Total views : 796